The Cropwalker - Volume 9 Issue 5

By Jonathan Zettler CPA, CMA, CCA-ON and Patrick Lynch CCA-ON

ALWAYS READ AND FOLLOW LABEL DIRECTIONS

CONFIDENTIAL NOT FOR PUBLICATION

Send us your questions

If you have a question, just reply to this email, we try to have an answer for you within 48 hrs. Or text Jonathan at 519 323 7505 or Patrick at 519 275 1058. If you want a topic researched let us know.

Unable to see pictures? Move this email to your inbox or ask your email app to download them. Usually at the top of the email in a header.

Things to do This Week

1. Make a list of current herbicides/fungicides/insecticides products in inventory, plan to use them up.

2. Update your field names/ field boundaries and A-B lines.

3. Plan/lay out projects /plots you want to run this year. Ideally these will line up with your equipment width, updated A/B lines/field boundaries when setting them up.

4. Check all grain storage bins for snow. Recent weather may have compromised your storage.

5. Make a list of all used equipment you can sell and plan to put in an auction. Used equipment should have good resale value going into spring. And you will be helping someone upgrade.

Cereals

Great Lakes Wheat YEN – Last Call

If you are thinking of signing up for the Great Lakes YEN, registration will be closing on February 23rd.

https://greatlakesyen.com/how-to-participate/

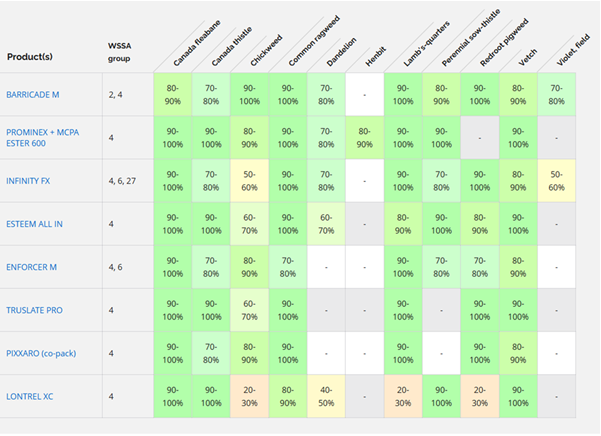

Q – I have fleabane in winter wheat, what are my best weed control options? (JZ)

A – Best in-class products from a crop safety and control standpoint contain either fluroxypyr and/or clopyralid. Because there are so many products on the market that can control fleabane, you should really be looking at what other winter weeds are in the field when making the herbicide decision. Almost all of the products control the common annual broadleaves without too many issues (Lamb’s Quarters, Pigweed, Common Ragweed). See chart below.

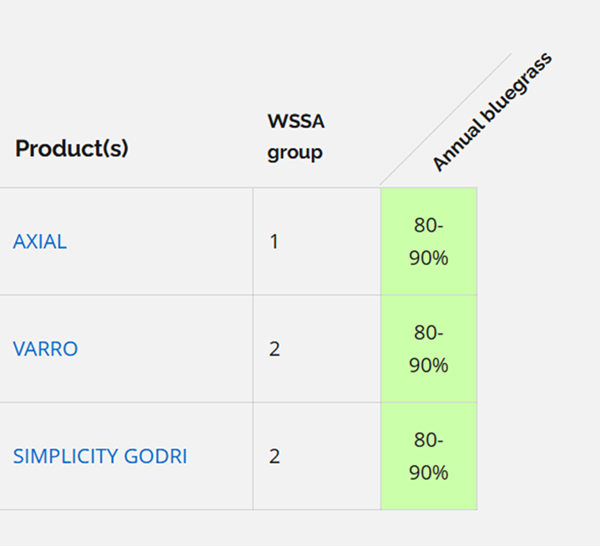

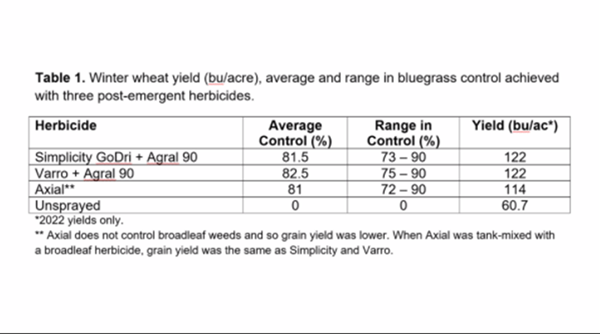

Controlling Bluegrass in Winter Wheat (JZ)

According to the Crop Protection Hub there are three herbicides registered that can control annual bluegrass species with varying success in winter wheat. Mike Cowbrough gave a presentation on the various success rates at the Weed Committee meeting in November.

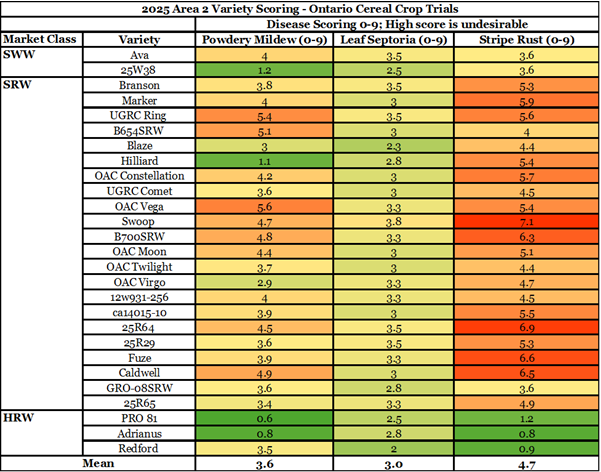

Q – I have been experiencing higher amounts of powdery mildew in my Winter Wheat; do you have any suggestions? (JZ)

A – As our level of management has increased, I have been observing much higher rates of powdery mildew in winter wheat. I’ve also noticed that the fungicides we are using are possibly not quite the right combination of actives and/or applied early enough to reduce the amount of infection we are getting on high pressure fields. I spoke with both Joanna Follings and Phil Needham about this issue and they offered the following suggestions.

1. Select varieties with good mildew resistance, especially when planted earlier or into higher fertility fields (too late for this crop at this point – but make note if you should push fungicide application earlier).

2. Fungicide when early signs of mildew are appearing (usually after the canopy starts to close in – especially in susceptible varieties). Tilt or its generic is reasonably effective, especially if applied early. I spoke with a few chem rep that suggested you need to use the high rate of Tilt or bump up the rate of propiconazole to at least the 200 mL/ac rate to get enough active on Mildew.

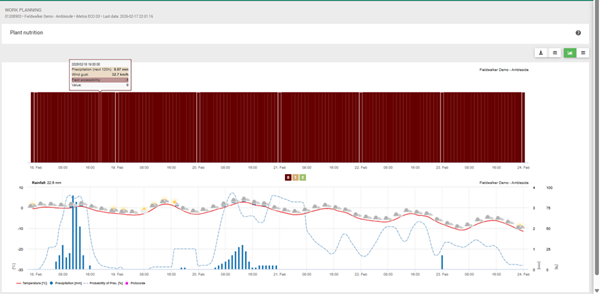

3. Temperatures above 25 C and above usually keep mildew in check. It likes coolish, damp weather. See example data below from one of my YEN fields where I had a weather station doing a mildew forecast.

Example – Disease Risk of Powdery Mildew in Winter Wheat

This field had a fair amount of powdery mildew, while the model can forecast infection risk, it cannot model variety or how heavy the pressure has historically been.

Weed Control

SWAC #32 Target Weeds Only Dr Tom Wolf (PJL)

WOW What a presentation. He showed us things that we did not even dream about 5 years ago. It has to do with spraying weeds. But it could eventually progress to spraying for insects and diseases. The basic concepts is to spray only certain areas vs. spraying the whole field. The decision is based on a camera identifying what should be sprayed.

1. Spray green on brown. Sprayers are set up to spray anything that is green. This is used in summer fallow in Australia and no-till burndown in Western Canada, and between rows in hort crops.

2. Spray green on green. The sprayer only sprays certain plants. Could spray only perennial sow thistle in winter wheat? A camera spots a plant and a computer tells the sprayer to spray.

3. The AI technology involves teaching a system to identify certain plants (weeds) in a crop.

4. This technology has been developed in part by Dr Geoffrey of the University of Toronto; He was part of the AI technology development. He received a Nobel Prize in 2024 for his work.

5. The technology now encompasses autonomous sprayers. He showed a video of an autonomous sprayer spraying weeds in a fallow field in Australia (this sprayer is branded as SwarmFarm).

6. The technology is expensive. John Deere charges $6 an acre for acres not sprayed using their technology. Then you must calculate if the savings in herbicide is off set by the charge per acre.

The following image depicts a sprayer equipped with an infrared camera that identifies weeds. The camera is aimed at about 3 meters ahead of the spray boom.

Right now, the cost means only growers with a very large acreage can afford the system. But I can envisage that within 5 years this system will be widely used in Ontario. Especially in hort crops and soybeans where weeds like palmer amaranth and water hemp are starting to flourish.

Corn

CCA – Tar Spot (JZ)

Notes from Dr. Darcy Telenko of Purdue Tar Spot update. She had 10 key points when it comes to this disease.

1. Every year has been different – disease triangle!

-Especially the favorable environment i.e., temperature, moisture, leaf wetness

2. Scouting is critical

-Need to understand current crop stage when infection occurs

3. Host resistance is important

-Hybrids variety in susceptibility to tar spot

4. Fungicides will work, but tar spot shows limitations

-Coverage is key when it comes to getting good control, tar spot is as good as water sensitive paper to show where coverage was poor.

5. Timing is critical – can be too early or too late

-Time for VT (tassel) to R3 (milk) for best possible benefit. R4 (dough) may have benefit if severe disease pressure year

6. ROI – understand the numbers on 1x vs. 2x applications

-In the US, generally do not need a 2nd spray unless you spray before or at tasseling.

7. Corn will never be 100% clean at the end of the season – see #4

8. Stewardship is important

9. Use the tools.

-Check out www.CropProtectionNetwork.org for tools to help manage this disease.

10. Keep asking new questions

Fertility

Value of Manure (PJL)

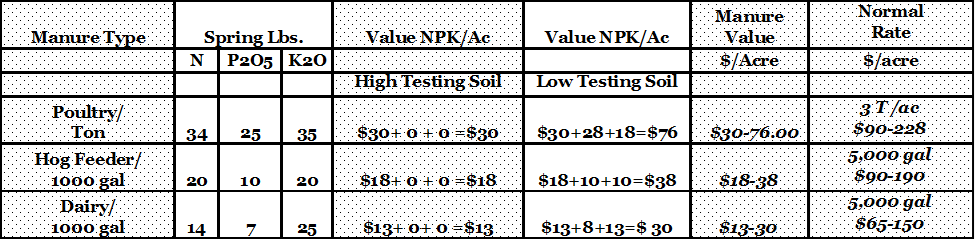

I cannot give a specific value of manure. Below are examples of average manure on real fields. The last column is the value at common application rates. To calculate the value of manure, you need the analysis and time applied. For nutrient values, I used $0.90 per lb. for nitrogen, $1.10/lb. phosphorous and $.50/lb. for potash. I have rounded numbers so values are not exact. But it does give you a perception of the value of manure. If the soil is testing over 35 ppm for phosphorous and over 160 ppm for Potash, do not give the manure P & K any value. I would use a portion of this value for P levels between 25 and 35 and K levels between 140 and 160. If P is in low 20’s and K under 140 use the highest values. These are values of manure applied so you must calculate an application cost. This is crediting only the nutrients available in the year of application. I did this exercise 20 years ago and N was $.34/lb. P was $.25/lb. and K $.19 /lb. Back then a livestock producer was money ahead to give the liquid dairy and some hog manure away since the application cost was higher than the nutrient value. These nutrient values are for average manure analysis so your value for sure will be different. These values are a bit higher than last year as the price on nitrogen and phosphorous are higher.

HAVE YOUR MANURE TESTED

Manure Credits – A review (JZ)

Nitrogen – measured in elemental, reported in elemental for fertilizer credit. Typically, the report is split into various nitrogen fractions - nitrate-N, ammonium-N and organic-N (OM%). The exact amount of the credit varies widely depending on the application method, timing and soil conditions.

i.e.

-hog manure applied in the summer on high pH soils on bare soil will experience significant N losses.

-solid beef manure is most available when applied in the mid to late fall, when it has chance to have microbes work on breaking down the organic fraction.

Phosphorus – measured in elemental, converted to P2O5 for fertilizer credit. Rule of thumb is 40% is available in year of application. 80% of total P2O5 is available for fertilizer credit. 20% is assumed to be tied up.

Potassium – measured in elemental K, converted to K2O for fertilizer credit. Since potassium is a water-soluble nutrient, rule of thumb is 90% of total K2O is available for fertilizer credit. 10% is assumed to be tied up.

Some additional notes:

Secondary and micronutrients – are all measured in elemental form and reported in elemental form – as phosphorus and potassium are the only fertilizer nutrients required by law to be reported in oxide form.

Sulphur in manure is in the elemental form and requires microbial activity to convert to the sulphate form to become plant available. Temperatures required for this are above 10 C.

Best data I have found if you would like more information is: https://fieldcropnews.com/2025/09/determining-the-available-nitrogen-from-manure/

Corn Starter Fertilizer Mixes [JZ]

Whether using an air cart or regular planter equipped to apply dry fertilizer planter here are some thoughts to try to minimize plugging and build ups.

1. There are many mixes using sulphur and magnesium. There are several grades of Sulpo-Mag (K-Mag). The only K-Mag sold in Ontario is the premium grade, which is made by granulation and is more susceptible to taking on water during days with high humidity. Typically, it is cheaper to buy K-Mag, than to try and make your own blend with Magnesium Oxy Sulphate and Potash, only reason to do this is if you can’t get K-Mag. Or are limited due to volume in the blend.

There are other brands of sulphate of potash magnesium sold on the market, if they look like cut glass, they can be extremely abrasive. This is fine for planters with a standard dry fertilizer box but will quickly wear out parts on an air system.

2. Looking to increase the flowability? Nutrien’s ESN or Purcell’s PurYield is an excellent option when looking to improve the flowability of a blend. With air carts/bins you are pushing moist air past the prills as it is being blown to the opener, as a result you end up with moist and sticky residues the entire length of the piping from Urea or ammonium sulphate. Dusty potash irritates this even more.

3. Mosaic’s MESZ may have a slight improvement in flowability over MAP. Especially if it has been oiled when leaving the terminal. An added benefit of MESZ is that you would not require Ammonium Sulphate in the blend, if looking to apply Sulphur in the band. Not accounting for nitrogen, 40 lbs of P2O5 from MAP, and 10 lbs of S from AMS, will take up more blend volume and have more flowability problems than just using MESZ. The MESZ combination has a lower salt index. See chart below.

4.There is limited benefit to placing boron in a 2x2 compared to broadcast. Due to boron toxicity and the low application rates. My rule of thumb, boron should be applied with the highest rate nitrogen application. Agronomists have commented on seeing a bigger yield bump by broadcasting over 2x2 applications. The use of Aspire (Mosaic’s granulated potash with boron), can reduce the risk of hot spots, if using boron in a 2x2 band. Not that that I recommend it, but an old rule of thumb I was told is to not use more than 1/10th of lb. of actual boron in a 2x2 starter band, which would be about 20 lbs of Aspire.

5. Adding liquid micros to a dry blend can cause additional issues. Mileage will vary depending on the underlying blend ingredients and the liquid micro formula base. Consider a drying agent in the blend, such as zeolite, kitty litter, or Agsorb to reduce issues.

SWAC #28 Fertilizer Philosophies Dr John Lauzon U of G (PJL)

A very interesting presentation if you are deep into soil testing and recommendations

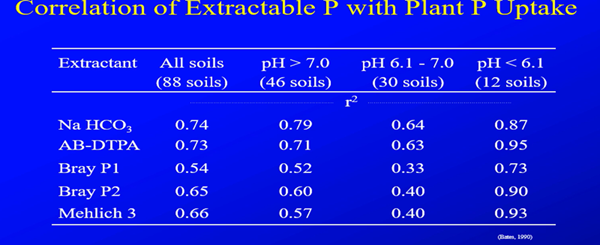

He explained how Ontario looked at various extractants to come up with using the Olsen method or Sodium bicarbonate (NaHCO3) to extract for phosphorous. This research was done in the late 80’s under Dr Tom Bates and he determined that for Ontario the sodium bicarbonate test was the most reliable for correlating a test to determine the amount of P taken up by plants. You can see below that it is not perfect but better than Mehlich 3.

He then went on to explain how research was done to come up with the chart we showed you last week on expectations for economic return for adding P at various soil test levels.

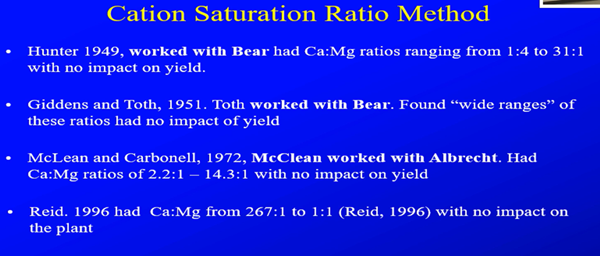

Then he gave the history of why some people use CEC as a basis for making fertility recommendations. He started with research started over 100 years ago and ended up with summaries of more recent research. This showed that there is no research to validate using CEC or ratios of nutrients to make fertility recommendations.

He pointed out that most labs do not do a real Cation Exchange Capacity extraction. They merely add up the cations and do a calculation. A real CEC calculation is a long expensive process that involves treating the soil with barium chloride to remove all the cations. Then you introduce a cation to see how many cations the soil can really hold. Very expensive and really of little value.

Business Matters

CCA – Balancing Cropping Decisions and Livestock Nutrition (JZ)

Deb Campbell of Agronomy Advantage and Simon Gladwell of Sharpe Farm Supplies did a duo presentation of how they helped a shared customer increase both milk and crop production. Much of the presentation focused on understanding full farm goals, benchmarking where they were relative to their peers, understanding the gap and how/where they could improve to reach what was possible. First the client put together a team of various subject matter experts/trusted advisors to help them achieve their goals. My key takeaways from this presentation is that the customer was willing to be brutally honest with key partners on their goals, and where they needed to improve. It is still a work in progress but seemed like they had achieved the first goals they were looking for. At times there are cropping decisions that will impact feed quality/volume, and they did speak to being at odds with that at times, but at least the farm could make trade-off decisions when everyone was at the table at the same time.

Using Weather Data - How a work planning tool can help with in-season cropping decisions (JZ)

FYI –These notes are from Metos/Pessl’s dealer meeting that I attended last week. I have been a dealer for about 2 years to provide their crop modelling and weather station solutions. I took on this dealership as I felt there was a need for a way to improve Ontario crop management through the use of weather and soil data, and the use of crop modelling could raise the bar. One of the crop modelling solutions is work planning tools, allowing you to have a calibrated way to make operational decisions on forecasted weather data.

I recently presented on how crop forecasting tools can help with in-season management decisions. The main decisions the work planning model can help with are:

1. Spraying conditions

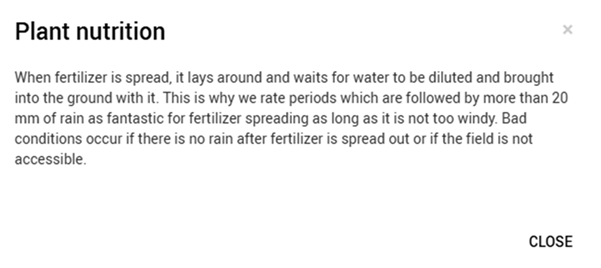

2. Nitrogen fertilizer application

3. Hay drying

4. Tillage/field accessibility

5. Sowing

There are other models available for disease/plant stage and yield forecasting.

One thing I liked about these tools when I look at them in-season, is they make it very clear what the risk or decision needs to be. Many times, I feel as agronomists we overcomplicate these decisions when the answer should be more black and white (or green/red) in the heat of the moment.

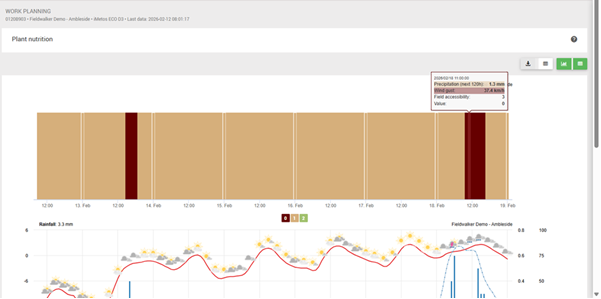

Example – suitability for nitrogen fertilizer applications

0 = unsuitable, 1 = caution, 2 = excellent conditions

When hovering over the colours, it will flag why the conditions might be unsuitable for the application.

Quality is not an act, it is a habit.

— Aristotle